October 4, 2018

|

|

|

Big brother is watching you! The tunnel web came is up and operational. Its temporary placement on top of the stereo system keeps on eye on the employees to ensure they aren't gold bricking! |

For the past nine months the Port of Whittier has served as a storage area for tools and materials. After LJ relocates everything to the children's play area the construction of the port begins to take shape. |

Tom and his adhesive gun are in full swing and he completes the cork road bed for the Flint Hills Refinery siding. |

|

|

|

Next, Tom tackles the notorious "S" curve with adhesive, cork and tape. |

Finally, Tom completes the cork road bed for the APU. Some switch repositioning took place so each of the stubs at Alaska Mill and Feed (northern end) could hold an Alaska Agriculture 4750 Cubic Foot 3-Bay Covered Hopper. |

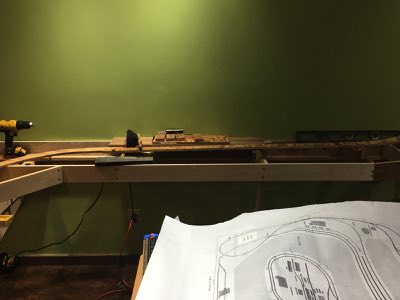

Mike and LJ have the plywood road bed in place for the mainline running past Whittier to the swing gate. |

|

|

|

Mike and LJ put the ribbing in place for the Port of Whittier. A rectangular area was left open for the barge which Tom is refurbishing. |

|

|

October 11, 2018

|

|

|

Foam board will be cut to go between the tracks on the layout. The top piece of foam board will be removable so I can work on scenery in a more convenient location. So where can I find foam board cheap? The HO scale Facebook group suggested checking job sites. A local dentist office was doing an expansion. Sure enough Foreman Logan said I could have five full sheets plus some scrap! |

I called the CFO to see if her Honda CRV would hold these sheets. After work she came down and we (in a pouring rain) tried unsuccessfully to load them. Ultimately, we placed them on top of my rear carrier and tied them down. We made it home without incident. |

The scrap pieces were covered in mud so we laid them out in the yard. The CFO hosed them off and after they dried put them in the garage with the full sheets. |

|

|

|

Several days earlier I pulled up all the tape which held the cemented cork bed in place. Tonight Tom finishes laying the track for the Anchorage and Alaska Marine Lines (AML) sidings. |

LJ called off work tonight due to a work call from his real job. Working solo Mike finishes securing the plywood road bed from the notorious "S" curve into the area of the Whittier subdivision. |

Using a piece of flex track Mike designs a gentle curve for the mainline running south of the Whittier division. Care must be taken to ensure the final stretch returns to "zero elevation" without dips or waves in the plywood. |

|

|

|

| Mike secures the mainline plywood road bed into place. Where is LJ when you need him? |

A very exciting moment occurs as the final piece of plywood road bed is put into place. With the exception of the swing gate, the road bed has now come full circle! |

To reiterate, the train layout basically runs in a complete circle. The installation of a swing gate will provide people access to the middle sections. Mike takes measurements to begin the design of the swing gate. |

|

|

|

|

| Tom completes track laying for the APU. Push pins serve as temporary track bumpers. |

The Alaska Agriculture covered hopper is put into place to confirm enough room exists for it on the stub siding. |

Tom completes the mainline track through the mountain curve and into the Usibelli Coal Mine. |

October 18, 2018

|

|

|

As carpentry and track laying draws to a close it is time to turn our thoughts to all things electrical. The layout will not use DC or DCC, but a newer system called RailPro. Mike, LJ and John spent the evening discussing RailPro, Tortoise switch machines and wiring. John pledges to make the order for the RailPro system tomorrow. |

Tom energetically places the cork road bed down through the notorious "S" curve, past the Port of Whittier and into the swing gate region. This is a view looking north. |

The same section, but this time looking east. The road bed at the bottom of the photo will connect to the swing gate. |

|

|

|

Tom lays the track through the Flint Hills Refinery siding as well as finishing the main. |

Tom continues laying track through the Mountain subdivision and into the Usibelli Coal Mine subdivision. |

|

October 25, 2018

|

|

|

High performance track laying machine ARR TK #1 installs rails from the Usibelli Coal Mine subdivision into the Notorious "S" curve section. |

Precision track laying through the "S" curve is critical to prevent any possibility of future derailments. |

LJ pops the shells of DCC ready locomotives to survey the future installation of RailPro circuit boards. Mike is not in attendance tonight as he is working on the swing gate off-site. |

|

|

|

Tom lays the track through the "S" curve, past the Port of Whittier and ends at the beginning of the swing gate. |

Tom installs the switch leading into the Port of Whittier. Further construction is delayed until the barge is put in place. |

View looking north of the notorious "S" curve as it leads to Whittier and the swing gate. |

|

|

|

A second view looking north. |

Since John is gone on a mini-vacation Zeus fills in as supervisor. If construction gets screwed up then blame it on Zeus! |

Tom puts down the adhesive for the cork road bed for the Usibelli Coal Mine siding. This will be the final time cork is laid until the barge is placed in the Port of Whittier. |

|

|

|

A partial shipment of RailPro products arrives! LJ spent the evening reading manuals and cramming his brain with lots of new stuff. |

RailPro handheld controller |

|