April 4, 2019

|

|

|

Tom and Mike discuss the next phase of the project: scenic backdrops and Styrofoam inserts. Eighth-inch masonite will be used and tacked to the wall. Double masonite walls with with wooden posts in the center will be used for the scenic backdrops in the center of the layout. John and Mike set up a Saturday time to run to the home improvement store to make the purchase of four 4'x8' sheets. |

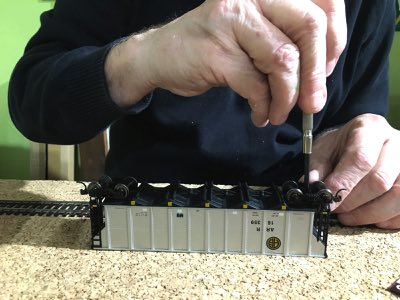

A previous derailment sent several hoppers to the floor resulting in a broken coupler. John purchased four sets on eBay and had them waiting for Tom to do his magic. |

Mike closes out all layout Tortoise adjustment issues with a fix on the APU main switch. |

|

|

|

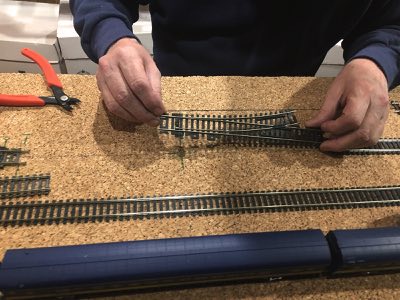

On a previous evening Tom noted there was room for one more track in the Anchorage yard and the crew gave him the green light. Tonight he installs the switch at the south end of the yard. |

Tom is lightning fast on laying the new track in the Anchorage yard. Next Thursday he will add the switch at the north end of the yard. |

Tom continues to work on the barge project at home by laying the new decking. Tonight he took home a box of flex track to extract the rails for the barge. |

April 9, 2019

|

|

|

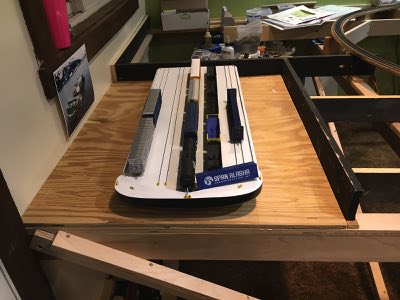

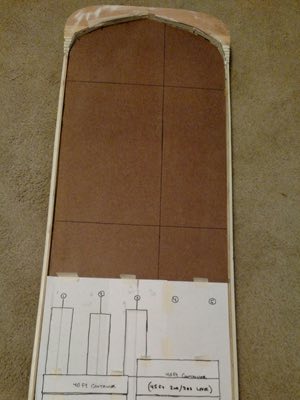

Tom was a busy beaver this week by working daily on the rail barge. The Hydro-Train model sent down from Seattle had experienced a lot of damage being moved from office to office as well as shipping it to Clayton, Ohio. Tom needed to shorten the barge to fit into the space we had, flatten the bottom, repair all damage and then paint. |

Ready for the flat hall. |

Hull glued, nailed and sanded. Will use filler on some seams then track and paint. |

|

|

|

Filler has been sanded. Added the detail parts. Ready for rails and paint. |

Laying track... |

Off to the paint shop... |

|

|

|

Will let the primer dry overnight. |

Deck is now white again. The hull gets a coat of black in the morning. |

Painting some of the details and cleaning paint off the rail heads. |

|

|

|

We are approaching greatness... |

Watching paint dry... |

|

April 11, 2019

|

|

|

Spring has finally arrived! Tonight's dinner is on the screened in back porch and features homemade spaghetti and meatballs, garlic bread and salads. |

Tom continues the work on the fifth Anchorage yard track by installing the north end switch. |

Tom ties in the track thus finishing the line. |

|

|

|

Now LJ installs a Tortoise switch machine at the north end of the new track. |

Next, LJ installs a Tortoise switch machine at the south end of the track. |

Although Ring Engineering has yet to return our repaired AM-1 LJ runs the communication lines in preparation for its installation. |

|

|

|

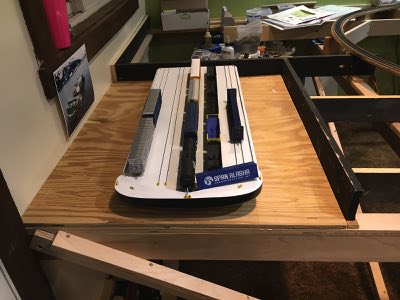

The layout achieves another level of greatness with Tom's delivery of the rail barge. Many hours of skilled craftsmanship is evident in this project! |

I recall opening the shipping box for this barge about a year ago and seeing dozens of small pieces fall out. Tom has meticulously cleaned, repainted and installed each and every one of them. |

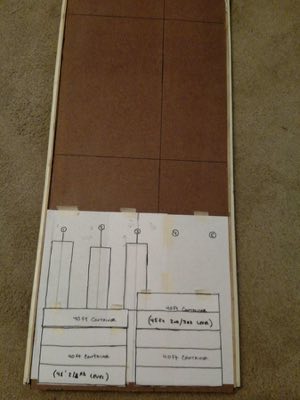

The original barge had eight tracks. This was impractical for my big hands so Tom installed five so I am able to handle the freight cars. Now all we need to do is figure out if an O scale transfer table will move this barge or if we will need to go another direction. Thoughts? |

|

|

|

Mike begins installation of the scenic backdrop using 1/8" hard board. |

The first install begins at the Flint Hills refinery. |

The backdrop continues north separating TwentyMile bridge and the double track. |

|

|

|

The backdrop rounds the curve at Portage depot and then heads south. |

Next week the backdrop will finish its run by separating Alaska Marine Lines and the APU. |

Leigh and LJ check out the operations of the switches at the south end of the Anchorage yard. After making a few adjustments LJ declares the entire layout is fully operational! |

|

|

|

John purchases a coupler height gauge which will be used on each and every car and locomotive to ensure they meet the standard. |

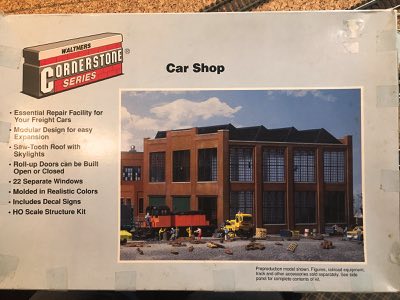

Since this is a fantasy layout John is not concerned with it being prototypical. Tom suggests using this car shop for the diesel house and John quickly agrees. Through a nice deal on eBay John purchases the HO Walthers Cornerstone Car Shop Building HO Kit and Heavy duty crane. |

Tom places the front wall of the car diesel shop on the tracks. He determines two of the tracks will need to be moved slightly so they are centered on the door openings. |

|

|

|

After moving the tracks Tom extended one of them so they all end in unison. |

Holding the wall in place gives a sanity check for proper locomotive clearance. |

Tom has been discussing ballasting procedures for the past several months. Prior to ballasting Tom suggested using Woodland Scenics Track Painter Pens on the rails and road bed. Although I did not say anything, I cringed inside knowing that these costs $8.00 each and a layout this size would require a butt load of them. Recently Tom saw someone using camouflage paint as a prep to ballasting. By coincidence the CFO had purchased this paint and had it downstairs. Tom spied the paint, built a short test track and applied it. He and I both agreed this will be a fast, easy and effective prep to ballasting. |

April 18, 2019

|

|

|

Mikel Levine is working on TwentyMile bridge in Cheyenne, Wyoming and needs clarification on construction size. A scale model of the bridge comes in at a whopping 6' 8". Our group evaluates the area and determines selective compression of the existing layout would make a full scale bridge appear too large. The crew decides a 4' model to be more particle. |

Mike continues to work on the scenery backdrop. Fortunately, the outdoor balcony provides a nice location for cutting and in this case, sanding. Belt sanding cleans up the end of the 1/8" hard board. |

Vertical risers are in place to hold the hard board. If necessary additional "above ground" supports can be added and blended into the existing scenery. |

|

|

|

The scenic back drop is now complete. This back drop separates the APU from Alaska Marine Line and TwentyMile from the double track. |

Due to a work commitment LJ arrives late, but hits the ground running. He installs the last of the eleven AM-1s, the two Tortoise switch machines for the track five north and south switches and then runs the power and communication lines. Sweaty work indeed! |

In some cases construction screws popped out of the other side of the wood leaving the sharp points exposed. Initially, John ground off the exposed points. However, 28 pairs of additional sharp daggers were located and John is trying to determine if there is an easier alternative to grinding. Maybe there are some kind of inexpensive caps that could be placed over the ends? If you have any ideas please send them to john@alaskarails.org. |

|

|

|

It is with a great deal of excitement that work begins at the Port of Whittier! Mike makes measurements for the plywood board on which the barge will rest. |

Although night has fallen the work continues! Mike uses a circular saw to cut through our last piece of plywood. I am thrilled that the old layout gave life to this new project. |

Measure one, cut twice. Or in this case cut three, four or five times until you get a perfect fit. The barge now resides in its final home and there is plenty of room for it to move back and forth for track loading. Now to construct a transfer table! |

|

|

|

Tom Terrific scarfed up the diesel shop and overhead crane kits and took them home to work on. He had them both finished the next day! He says of his work, "Having fun Part 1. The rear side. One door shut. Two doors mostly open for the view...". |

He continued saying, "Having fun Part deux. All front doors wide open. Will dull coat the entire structure then add windows. Overhead crane is made to fit the Walthers back shop... You have the car shop. I will make it work...". |

He also took home the camouflaged painted test track to add ballast. Assuming the proposed technique obtains the CEO's approval, full scale production will begin. |