|

||

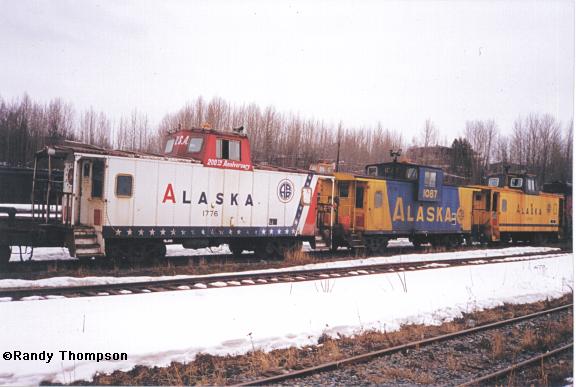

With most railroads retiring cabooses as a cost savings, the Alaska Railroad continues to utilize this valuable resource. Basically a caboose is just a rear observation deck. On long trains there is no way to see what is going on with the rear half of the train. There could be sliding or broken wheels, bearing failure, shifted or dragging equipment, derailment, shifted or dragging loads, fire, etc. So cabooses (cabeese?) were added long ago to, if not prevent entirely, at least lessen, the damage to the equipment, track, environment, and the public. The crewman can keep an eye on air pressure in the brake line at the back of the train (End of Train devices have basically eliminated this function). Specifically, the ARRC uses cabooses mostly for commercial gravel trains because of the length of the train and all the cutting apart of the equipment, lining behind of switches, and such involved with its daily operation. They are used on company (non-revenue) work trains so that those trains can run backwards with out switching the train around so many times. Company work trains run backwards nearly as much as they run forwards, to and from the loading and dump site. Cabooses are also used on the Whittier Shuttle. The train hauls both vehicular traffic as well as foot passengers. The caboose on this train is used by the conductor basically as an office on the Inbound to Whittier leg of their trip. The baggage car is used for that purpose on the trip from Whittier to Portage. Cabooses are also used as "station wagons" to haul student train/enginemen to the training grounds on Fort Richardson Army Base. Finally, since all of the switches are thrown by hand, a caboose can put someone instantly at a switch. And this from an ARR conductor, "When two trains meet nowadays without cabooses, the shortest train usually takes the siding. Two man crews means the conductor gets off at the switch, lines the train in, and then stands there until the train is completely in the siding and then lines the mainline turnout back green. The other train goes by and after it gets one mile away it calls and lets us know. We call the dispatcher who gives us track authority from that point one mile back and then onward. The dispatcher gives us permission to back up one train length without flagging (moose, kids, snowmobilers be damned...they are all trespassers) and the conductor throws the switch, back up out of the siding , re-align the switch & on we go. It is pretty cold standing there so we wait til the meeting train gets close before pulling in the hole and clearing. I hate this system....wish we had brakemen and cabooses again. So much easier."

|

||

Click on the pictures below for a larger view.

|

||

|

||

|

||

|

||

You'll find an incomplete caboose inventory here Cabooses are being replaced by a wide variety of electronic components. The following is a list of the more common types: FRED EOTD Defect Detectors The ARRC uses 4 types of detectors. They are: Type A: Dragging Equipment Detector. Dragging equipment detectors detect any equipment dragging on top of ties. Type B: Dragging Equipment/Hot Bearing Detector. Same as A, and/or any hot bearings (ambient temperature plus 172 degrees F. or 120 degrees F. temperature variance between ends of same axle). These detectors will communicate total axle count after train clears the circuit. Type C: Dragging Equipment/Hot Bearing/Hot Wheel/High or Wide Clearance Detector. Same as B, plus any hot wheels (440 degrees F.) and/or any high or wide clearance (19' 4" high and / or 13' 6" wide.) Trains moving at 20 MPH or less are likely to set off detect for "clearance defects" due to agitated snow. Type D: Dragging Equipment Detector. Same as A, but only activates if anything is dragging. Once activated it can only be reset by signal maintainer and will not be operational again, until reset. All type "D" defects are to be reported to Train Dispatcher.

|

||

Thanks to Duane Frank and Frank Dewey for providing this information! © 1998-1999 John Combs unless otherwise noted |